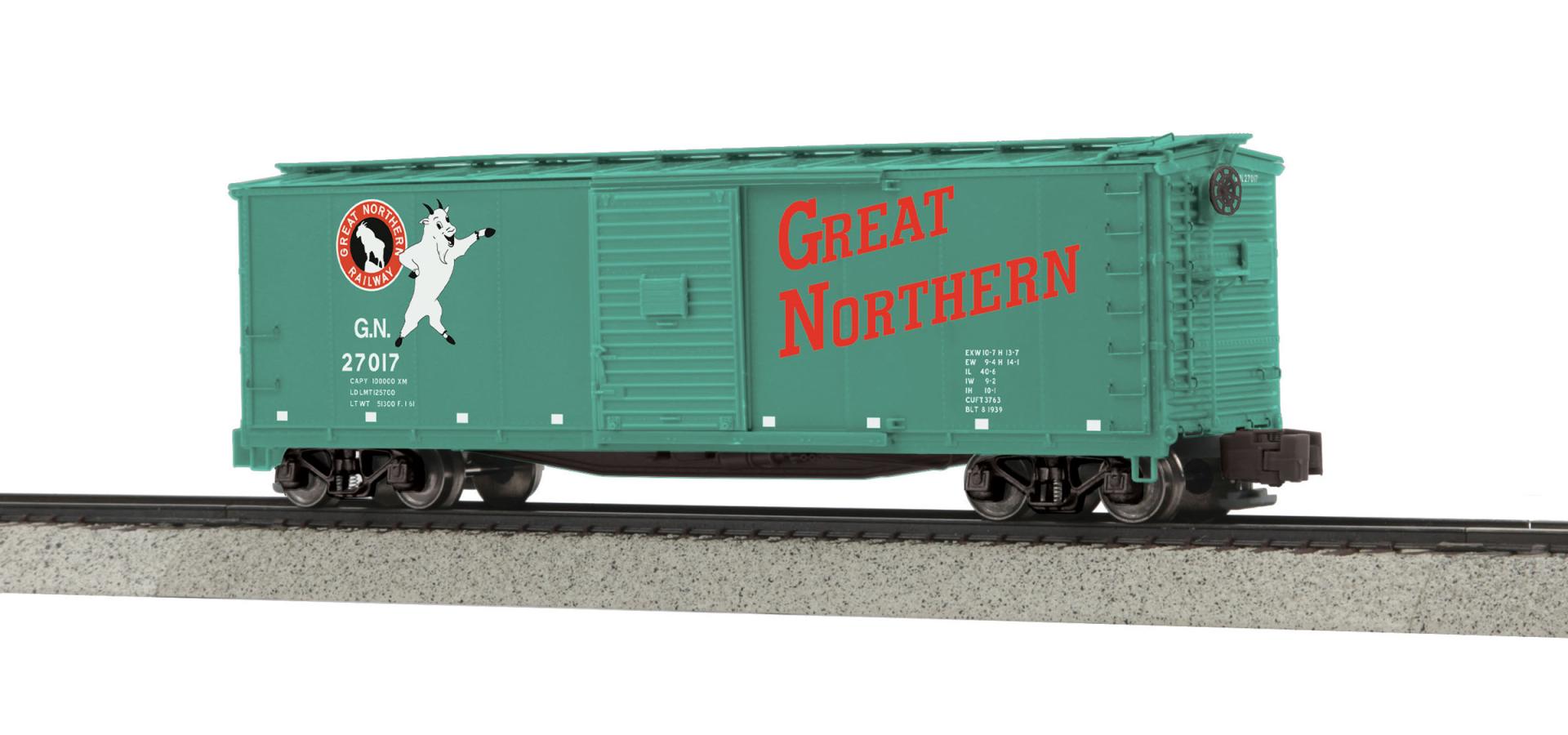

Great Northern S Gauge MTH S Gauge Rebuilt Steel Box Car (Scale Wheels)

Overview

During and after World War I, American railroads took delivery of tens of thousands of boxcars built to USRA designs: single or double-sheathed wooden sides, wooden doors, and steel ends, roofs and underframes. By the late 1920s, however, all-steel cars had become the norm, although new car construction slowed to a crawl during the Depression.

A cheaper alternative was rebuilding older USRA cars, replacing the wooden sides and doors with steel and re-using the existing underframe, ends, and/or roofs. Brake systems were also upgraded, from the earlier K-brake to the more modern AB brake system. As World War II loomed and traffic began to pick up, railroads upgraded thousands of USRA boxcars to all-steel construction, usually doing the work in their own shops. Rebuilding programs continued through and after the war, and steel rebuilt cars were a common sight into the late 1950s, with many serving into the following decade.

While rebuilt car details often differed from railroad to railroad, a spotting feature common to most of the cars was the sill brackets added to the existing underframe side sills - a feature replicated on these M.T.H. models. These sill brackets supported new steel sides that were spaced father apart than the old wooden sides, making a wider car with greater carrying capacity.

Features

- Intricately Detailed, Durable ABS Body

- Colorful, Attractive Paint Scheme

- Metal Wheels and Axles

- Detailed 4-Wheel Trucks

- Needle-Point Axles

- American Flyer-Compatible Coupler

- S Scale Kadee-Compatible Coupler Mounting Pads

- Detailed Brake Wheel

- Separate Metal Handrails

- Sliding Car Doors

- 1:64 Scale Dimensions

- Unit Measures: 8 13/16" x 1 7/8" x 2 9/16"

- Operates On 20" Radius Curves